Should I Choose a Vented or an Unvented Water Cylinder?

When it’s time to replace your hot water cylinder, you may find yourself wondering which type you should choose – vented or unvented? This article aims to explain the difference between them and will help you decide which type would be better for your home and budget.

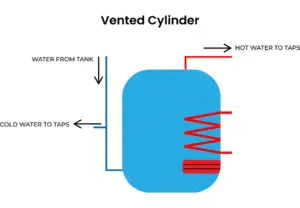

Vented cylinders (Gravity Fed Hot Water Systems)

Vented cylinders – also known as open-vented cylinders, are fed by a large cold water tank. This tank is located as high in the house as possible (usually in the loft) as the pull of gravity is needed to vent the water down to the hot water cylinder where the water is heated. The higher the tank, the greater the water pressure.

Once the water heats up, it will expand. The vent pipe and the loft tank safely allow for this expansion.

Are Vented Cylinders Eco Friendly?

Older vented cylinders are traditionally made of copper. Unfortunately they aren’t really eco friendly due to the amount of heat loss they suffer. Lagging is one way to lessen heat loss for old cylinders but you’ll find that new cylinders are pre-sprayed with insulating material, which minimises heat loss.

Advantages

• Cheap to install as they are simple and basic.

• In the event of loss of mains water, you still have a tank full of water in the loft.

Disadvantages

• The effect of gravity on water pressure means the taps and showers downstairs will be less powerful than the ones upstairs

• You may need to boost flow, particularly to showers with an electric pump (power shower for instance). Vented installations won’t usually deliver hot water at the pressure of an unvented system.

• You will need storage space in your loft for a cold water tank if you haven’t already got one.

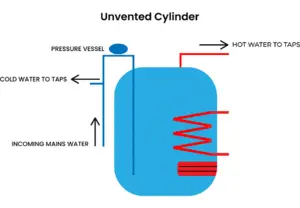

Unvented Cylinders

Unvented cylinders are fed directly from the cold water mains, so there is no need for a water storage tank.

There are two types of unvented cylinder:

1. Direct Model:

the unvented cylinder is kept under pressure by water coming straight from the mains supply and is directly heated by immersion heater.

2. Indirect Model:

the water is heated either by either a heat source external to the cylinder ie a boiler, or by a wet solar system.

Unvented cylinders have multiple pipes connecting and distributing hot water to outlets around the house. As soon as an outlet (tap or shower) is turned on, the hot water that leaves the cylinder is replaced by mains pressure cold water.

Because they are ‘sealed’, unvented systems need an expansion vessel for safety. This can either be next to or incorporated within the boiler or cylinder. An expansion vessel is vital to cope with increased pressure as water heats up and expands, making for a safe, easy to use system.

Advantages

• No water tank needed, so saves space.

• Can be installed anywhere as there is no reliance on gravity.

• Quieter. No sound of water filling as with a vented system.

• Potential for a good flow rate as they operate under mains pressure (this depends on the incoming mains pressure).

• Completely sealed system, so no risk of it freezing in the winter or being contaminated by anything in the loft.

Disadvantages

• Initial outlay more expensive as the system is more complex and fitting costs are higher.

• No hot water if the mains gets turned off.

• May not be compatible with all types of shower or mixer tap.

• Dependent on incoming mains pressure being strong enough. This needs to be checked by a registered engineer with a qualification to work on unvented cylinders.

Conclusion

Despite the higher cost of the purchase and installation, unvented cylinders are generally thought to be the better choice for either new installations or replacement cylinders. Not only do they offer plenty of stored hot water on demand, they also work at mains pressure, which provides an excellent flow rate with no need for a power shower pump.

When Should I Replace My Hot Water Cylinder?

You can reasonably expect a well-fitted hot water cylinder to last for at least 30 years. Look out for any signs of leakage, particularly damp patches around the cylinder. At the first sign of any leaks, make sure to act quickly and prevent expensive water damage to your property.

Remember, all unvented cylinder work must be carried out by an engineer qualified to work on them.

WaterGuys are Gas Safe registered engineers, with many years’ experience working on unvented cylinders.

Contact us on 020 313 77749 for a friendly chat. We’re always happy to advise on the best cylinder type for your home.